IIS Manufactures & Supplies Torsion Spring

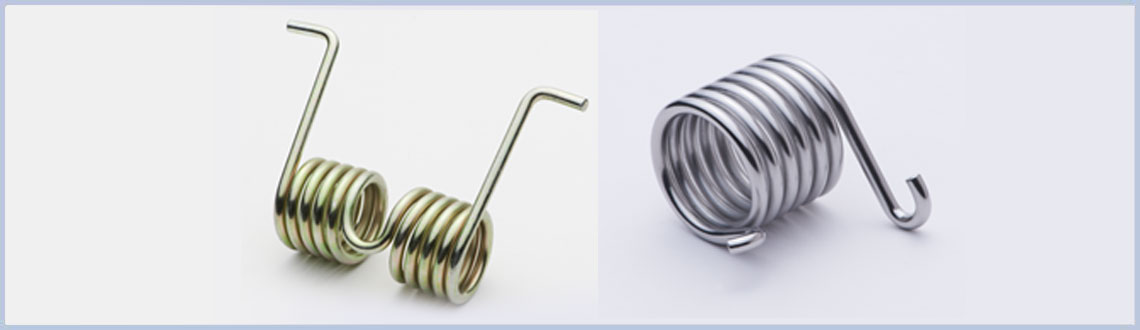

TORSION SPRINGS

Torsion Springs resist external torque with angularly deflecting ends. Contrary to its name, the wire is subjected to bending stress and not torsional stress. These are close wound springs. After deflection, the body length increases and coil diameter reduces.

Installation

Spring load and deflection largely depend on the type of end and installation. Every torsion spring will have two points of contact at the end and one at the arbor. While designing, the position of the contact points and their relative position should be made clear.

Types of Ends

A great care must be taken while deciding spring ends as different types of ends and special end forming result in higher cost and frequent tool change.

Spring Materials - Common spring materials include stainless steel, alloy steels, carbon steels and some non-ferrous materials. IIS also produces spring from Exotic material like Inconel X-750, Inconel 718, Nimonic 90, Monel, Nimonic, Hastelloy, Beryllium copper etc.

Spring design – IIS can design torsion springs for you depending on your application, space and torque requirement. IIS can manufacturer torsion springs with all types of ends and sizes. Please send us your requirement and we will be free to help you.

Surface coating – IIS offer a variety of coating on springs like Mechanical Zinc plating, Zinc Electro plating, Nickel Plating, Electrolysis Nickel plating, Geomet, Daromet coating, Cadmium plating, Powder coating, Epoxy painting etc.

Torsion springs are manufactured to DIN 2194 & EN13906