|

|

DISC

SPRING INSTALLATION, SETTING & STACKING

Installation:

| a) |

Dynamic

applications, involving large numbers of deflection

cycles, will require that in addition to hardened

seating faces the guide surfaces must also be sufficiently

hard to prevent excessive wear or "stepping".

For both support washers and guide elements, a polished

surface with hardness of 58HRC is sufficient, and

case depth should be 0.60mm min.

|

| b) |

A

most important aid to efficient and extended life

of Disc Spring is the provision of some form of

lubrication. For relatively low-duty Disc

Spring application, a liberal application of suitable

solid lubricant, (e .g. molybdenum-disulphide, grease),

to the contact points and locating surfaces of the

spring is adequate.

|

|

|

For more severe applications of a dynamic or highly corrosive

nature, the Disc Springs will benefits from maintained lubrication,

and are often housed in a oil or grease filled chamber.

............................................................................................................................................

|

|

|

Disc

Spring with Contract Flats and Reduced Thickness:

For

Disc Springs with a thickness of more than 6mm, DIN 2093

specifies small contact surfaces at point I III in Addition

to the rounded corners. These contact flats improve

definition of the point of load application and reduce

friction at the guide rod. Contact flat increase

spring load which is to be compensated by a reduction

in the thickness from 't' to 't'.

|

|

............................................................................................................................................

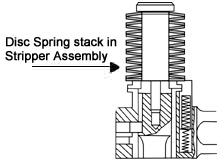

Stacking

:

|

|

Series

Stacking: The cumulative effect of bearing point friction

of large numbers of Disc Springs stacked in series, can

result in the Disc Springs at each end of the stack deflecting

more than those in the center. In extreme cases this may

result in over-compression and premature failure of the

end springs. A “rule of thumb” is that the length of the

stacked Disc Springs should not exceed a length approximately

equal to 3 times the outside diameter of the Disc Spring.

|

| Stack

Length : |

|

|

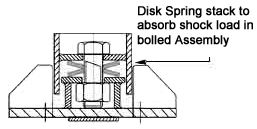

When

stacking Disc Springs, effort should be made to keep the

stacks as short as possible. Friction and other

influences make a stack more uneven. It deflects

more on the side of the loading. This effect usually

can be neglected for a "normal" spring stack,

but not for long stacks. If it is longer, the stack

can be stabilized by dividing it with guide washers, which

as a rule of thumb should have a thickness of at least

one and a half times the guide diameter.

|

|

Address : Plot

No. A-26, Road No. 10, Wagle Industrial Estate, Thane - 400604,

Maharashtra, INDIA

* Tel. : 2582 1941 / 2508 / 2581 3416 * Fax : 91-22-2582

4478

* Email : sales@internationalsprings.com

|

|