IIS Manufactures & Supplies E-Clip DIN 679

IIS Manufactures and supplies E-Clips with high end quality metals and precision machine. Quality such as high strength, perfect finish, excellent durability owing attributes durability. These are easily available at leading market prices. The most common Application is of radially fitted Circlips for shafts with grooves which provide a large shoulder on a relatively small shaft diameter.

Material :

Carbon Spring steel ( DIN17222 / EN10132-4 )

Carbon Spring steel Hardened and Tempered

Stainless Steel 301 / 304

Inconel X 750 and X718

Surface Finish :

Phosphate ( IS 3618 )

Electro Zinc Plating ( IS 1573 )

Mechanical Zinc Plating (ASTM B695)

Polish Finish for Stainless Steel

Natural Finish

Stock :

All STD Sizes are available.

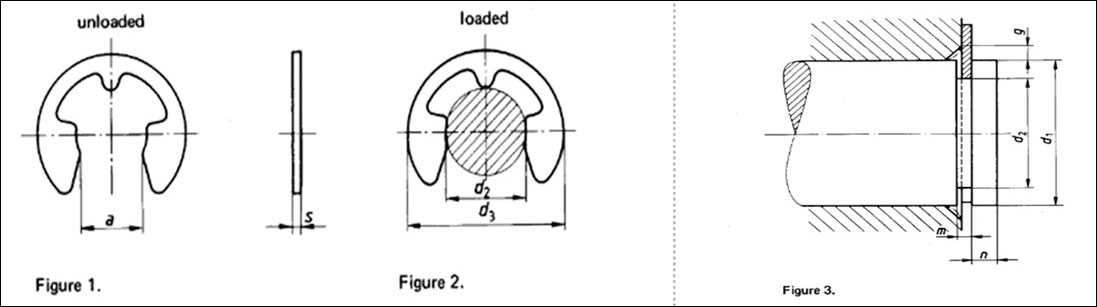

| E-Clip DIMENSION Table:- | ||||||||||||||||||||

| Part No. | WS NO. | Groove Diameter | Shaft Diameter Range | Lock Washer | Groove | Supplementary Data | ||||||||||||||

| d2 (mm) | d1 from to | s (mm) | Tol. (mm) | a (mm) | Tol. (mm) | d2 | Tol. (h11) (mm) | m | Tol. (mm) | n (min.) | d3 max | Fn kN at d1' | Fs kN</td> | g | Fsg kN | nab1 min |

||||

| EC2.25X0.58X0.2NF | 8664 | 0.8 | 1 | 1.4 | 0.2 | ± 0.02 | 0.58 | ±0.04 | 0.8 | -0.04 | 0.24 | +0.04 | 0.4 | 2.25 | 0.03 | 1.2 | 0.08 | 0.3 | 0.04 | 50000 |

| EC3.25X1.01X0.3NF | 8665 | 1.2 | 1.4 | 2 | 0.3 | 1.01 | 1.2 | -0.06 | 0.34 | 0.6 | 3.25 | 0.04 | 1.5 | 0.12 | 0.4 | 0.06 | 47000 | |||

| EC4.25X1.28X0.4NF | 8666 | 1.5 | 2 | 2.5 | 0.4 | 1.28 | 1.5 | 0.44 | 0.8 | 4.25 | 0.07 | 2 | 0.22 | 0.6 | 0.11 | 43000 | ||||

| EC4.8X1.61X0.5M1.9NF | 8667 | 1.9 | 2.5 | 3 | 0.5 | 1.61 | 1.9 | 0.54 | +0.05 | 1 | 4.8 | 0.10 | 2.5 | 0.35 | 0.7 | 0.17 | 40000 | |||

| EC6.3X1.94X0.6M2.3NF | 3299 | 2.3 | 3 | 4 | 0.6 | 1.94 | 2.3 | 0.64 | 1 | 6.3 | 0.15 | 3 | 0.5 | 0.9 | 0.24 | 38000 | ||||

| EC7.3X2.7X0.6M3.2NF | 8668 | 3.2 | 4 | 5 | 0.6 | 2.70 | 3.2 | -0.075 | 0.64 | 1 | 7.3 | 0.22 | 4 | 0.65 | 0.9 | 0.32 | 35000 | |||

| EC9.3X3.34X0.7M4NF | 3409 | 4 | 5 | 7 | 0.7 | 3.34 | ±0.048 | 4 | 0.74 | 1.2 | 9.3 | 0.25 | 5 | 0.95 | 1 | 0.47 | 32000 | |||

| EC11.3X4.11X0.7M5NF | 3410 | 5 | 6 | 8 | 0.7 | 4.11 | 5 | 0.74 | 1.2 | 11.3 | 0.90 | 7 | 1.15 | 1 | 0.60 | 28000 | ||||

| EC12.3X5.26X0.7M6NF | 3411 | 6 | 7 | 9 | 0.7 | 5.26 | 6 | 0.74 | 1.2 | 12.3 | 1.10 | 8 | 1.35 | 1.1 | 0.70 | 25000 | ||||

| EC14.3X5.84X0.9M7NF | 3412 | 7 | 8 | 11 | 0.9 | 5.84 | 7 | -0.09 | 0.94 | 1.5 | 14.3 | 1.25 | 9 | 1.80 | 1.3 | 1.00 | 22000 | |||

| EC16.3X6.52X1M8NF | 3413 | 8 | 9 | 12 | 1 | ± 0.03 | 6.52 | ±0.058 | 8 | 1.05 | +0.08 | 1.8 | 16.3 | 1.42 | 10 | 2.50 | 1.5 | 1.25 | 20000 | |

| EC18.8X7.63X1.1M9NF | 8670 | 9 | 10 | 14 | 1.1 | 7.63 | 9 | 1.15 | 2 | 18.8 | 1.60 | 11 | 3.00 | 1.6 | 1.50 | 17000 | ||||

| EC20.4X8.32X1.2M10NF | 7001 | 10 | 11 | 15 | 1.2 | 8.32 | 10 | 1.25 | 2 | 20.4 | 1.70 | 12 | 3.50 | 1.8 | 1.75 | 15000 | ||||

| EC23.4X10.4X1.3M12NF | 6543 | 12 | 13 | 18 | 1.3 | 10.45 | ±0.07 | 12 | -0.11 | 1.35 | 2.5 | 23.4 | 3.10 | 15 | 4.00 | 1.9 | 2.30 | 13000 | ||

| EC29.4X12.61X1.5NF | 8673 | 15 | 16 | 24 | 1.5 | 12.61 | 15 | 1.55 | 3 | 29.4 | 7.00 | 20 | 7.80 | 2.2 | 3.30 | 11000 | ||||

| EC37.6X15.92X1.75NF | 8674 | 19 | 20 | 31 | 1.75 | 15.92 | 19 | -0.13 | 180.00 | 3.5 | 37.6 | 10.00 | 25 | 11.00 | 2.5 | 3.60 | 7600 | |||

| EC44.6X21.88X2M24NF | 8675 | 24 | 25 | 38 | 2 | 21.88 | ±0.084 | 24 | 2.05 | 4 | 44.6 | 13.00 | 30 | 15.00 | 3 | 4.00 | 5500 | |||

| EC44.6X21.88X2M24NF | 8676 | 30 | 30 | 42 | 2.5 | 25.80 | 30 | 2.55 | 4.5 | 52.6 | 16.50 | 36 | 23.00 | 3.5 | 5.30 | 4200 | ||||